Reducing Contaminants for Flawless Paint Finishing

Achieving flawless paint finishing isn’t solely about skillful application techniques or premium paint products. It’s also about creating an environment that fosters pristine conditions for every brushstroke and spray.

Imagine meticulously applying layers of paint, only to find imperfections mar your final masterpiece. These imperfections aren’t merely flaws; they’re often the result of unseen contaminants lurking in your paint booth environment.

Table of Contents:

Section 1: Understanding Pollutants in Paint Booths

Section 2: Impact of Contaminants on Paint Finishing

Section 3: Strategies for Contaminant Control

Section 4: Choosing the Right Air Filtration System

Section 5: Best Practices for Contaminant Management

Understanding Pollutants in Paint Booths

Definition of contaminants

In simple terms, contaminants are any unwanted substances that find their way into your paint booth environment. They’re the tiny particles and impurities that float in the air or settle on surfaces, waiting to disrupt the smooth application of paint.

These contaminants may seem insignificant individually, but collectively, they can spell disaster for your finishing efforts, manifesting as flaws, imperfections, or adhesion issues.

Common sources of contaminants

Dust, debris, and airborne particles are among the most common culprits when it comes to paint booth contamination.

Dust particles can enter the booth from various sources, including ventilation systems, open doors or windows, and even the clothing or skin of personnel.

Debris, such as paint chips or residue from previous jobs, can also contaminate surfaces and affect the quality of the finish.

Additionally, airborne particles like pollen, mold spores, or industrial pollutants can find their way into the booth, posing a threat to the integrity of your paint job.

Impact of Contaminants on Paint Finishing

Pollutants interfere with paint adhesion, preventing the paint from properly bonding to the surface. This can lead to peeling, flaking, or uneven coverage, compromising the durability and longevity of the finish.

Moreover, contaminants can mar the surface quality of your paint job, leaving behind unsightly blemishes, streaks, or texture irregularities.

Lastly, contaminants can tarnish the overall finish of your paint job, leaving it looking lackluster or subpar. Even if the paint adheres adequately and the surface appears smooth, the presence of contaminants can create a dull, matte appearance or cause light to refract unevenly, resulting in an unpolished finish.

Examples of common paint defects

Fisheyes are perhaps one of the most notorious paint defects caused by contaminants. These circular or crater-like blemishes form when silicone, oil, or other surface contaminants repel the paint, leaving behind unsightly gaps in the finish.

Orange peel is another common paint defect associated with contaminants. This texture irregularity resembles the surface of an orange peel, characterized by small bumps or dimples that disrupt the smoothness of the finish. Contaminants such as dust or debris can interfere with the paint’s flow and leveling, leading to this undesirable texture.

Surface imperfections, including scratches, pits, or streaks, are often the result of contaminants that become trapped in the paint film during application. These imperfections detract from the overall quality of the finish, creating an uneven or flawed appearance that falls short of professional standards.

Strategies for Contaminant Control

Controlling contaminants in your paint booth environment is crucial for achieving flawless paint finishing.

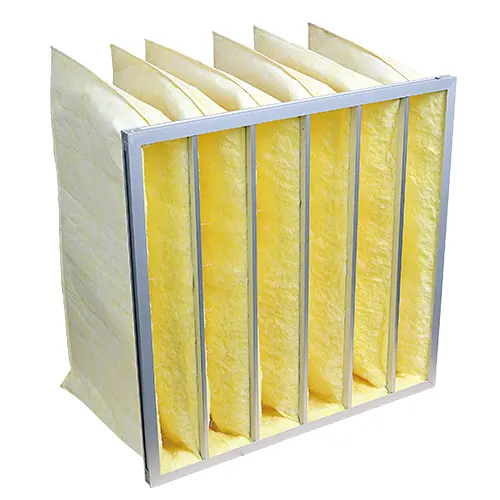

Implementing effective air filtration systems

Investing in high-quality air filtration systems is paramount for keeping airborne contaminants at bay. Paint booth intake filters are particularly effective at capturing even the smallest particles, ensuring that the air circulating within your paint booth is clean and free of pollutants.

Regularly replacing filters is essential to maintain optimal filtration efficiency and prevent contaminants from accumulating.

Maintaining a clean and organized work environment

A cluttered or dirty workspace can serve as a breeding ground for contaminants, compromising the quality of your paint finishing. Establishing strict cleanliness protocols and regular cleaning schedules is essential for minimizing dust, debris, and other surface contaminants.

Controlling humidity levels

Humidity fluctuations can wreak havoc on paint adhesion, leading to issues such as blistering, peeling, or wrinkling.

Investing in a reliable humidity control system, such as dehumidifiers or HVAC units with integrated humidity sensors, can help maintain stable moisture levels within the paint booth environment.

Choosing the Right Air Filtration System

Factors to consider when selecting air filtration systems for paint booths

Filtration Efficiency: Seek air filtration systems compatible with high-efficiency particulate air (HEPA) filters or similar technologies, allowing for future upgrades or the need to filter the smallest particles.

Airflow Capacity: Consider the size and airflow requirements of your paint booth when selecting a filtration system. Ensure that the system you choose can provide sufficient airflow to adequately ventilate the booth and maintain a clean working environment.

Compatibility with Paint Materials: Certain paint materials may require specific filtration requirements. Ensure that the filtration system you choose is compatible with the types of paints and coatings you use to prevent any adverse reactions or contamination issues.

Durability and Reliability: Look for a filtration system that is built to withstand the demands of continuous operation in a paint booth environment.

Filters for Paint Booths

Best Practices for Contaminant Management

Establishing regular cleaning and maintenance schedules

Regular cleaning and maintenance are essential for keeping your paint booth equipment and surfaces free of contaminants. Establishing a comprehensive cleaning schedule ensures that all areas of the booth are regularly inspected, cleaned, and maintained to prevent the buildup of dust, debris, and other contaminants.

This includes cleaning ventilation ducts, replacing filters, spray booths, floors, and walls to maintain a clean and contaminant-free environment.

Implementing containment measures to prevent contaminants

Preventing contaminants from entering the paint booth environment is key to minimizing their presence and ensuring flawless paint finishing.

Additionally, establishing designated entry and exit points with proper airlocks and filtration systems can further reduce the risk of contaminants entering the booth.

Conclusion

Reducing contaminants isn’t just about maintaining a clean workspace; it’s about ensuring the integrity and quality of your paint finishing. Contaminants can compromise adhesion, surface smoothness, and overall finish, leading to unsightly defects and compromised durability.

By prioritizing contaminant control measures, you can create an environment that fosters flawless paint finishing, exceeding expectations and ensuring customer satisfaction.

In essence, minimizing contaminants isn’t just a best practice; it’s a fundamental aspect of achieving excellence in paint finishing.

By implementing the strategies and best practices discussed in this guide, you can create a cleaner, more controlled, and safer paint booth environment conducive to flawless paint finishing results.