The Science Behind High-Temperature Air Filters: How They Work and Why They Matter

Table of Contents:

Section 1: What Are High Temperature Filters

Section 2: How High Temperature Air Filters Work

Section 3: Applications of High Temperature Air Filters

Section 4: CleanLink Offers Quality High Temperature Filters

Section 5: The Importance of High Temperature Filters

High temperature air filters are vital components in HVAC systems in various industrial processes that require clean air at higher-than-usual temperatures.

These filters are designed to maintain their integrity and performance under extreme conditions, ensuring the protection of sensitive equipment and the quality of the final products.

What Are High Temperature Filters

Definition

High temperature air filters are engineered to operate effectively, safely, and continuously in environments where air temperatures can reach extreme levels.

These filters are critical in applications where maintaining air purity is essential with high temperatures.

The primary purpose of high temperature air filters is to remove contaminants and particulates from the air, ensuring that clean air is delivered to sensitive processes and equipment.

Key Features

1. Heat-Resistant Materials

High temperature air filters are made from materials that can withstand extreme heat without compromising functionality. Common materials include fiberglass and synthetic fibers with special treatments.

These filters maintain their structural integrity and filtration efficiency even under high-temperature conditions.

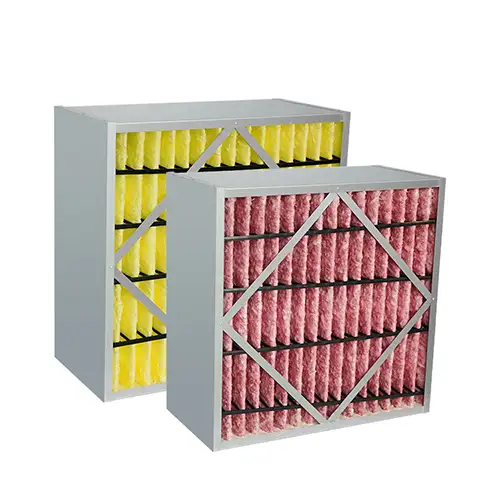

2. Robust Structural Design

To be effective in working with high temperatures, these filters often have robust frame structures and supports.

This structural robustness ensures that the filter remains intact and functional, preventing any deformation or damage that could compromise its performance.

3. High Filtration Efficiency

High temperature air filters are specialized filters that capture a wide range of particulates in high temperatures, including fine dust, smoke, and other airborne contaminants.

They often meet stringent industry standards for filtration efficiency, such as EN779.

4. Durability and Longevity

These filters are designed to last longer than standard air filters in extreme working conditions.

Their durable construction and high-quality materials contribute to a longer service life, reducing the frequency of replacements and minimizing maintenance costs.

How High Temperature Air Filters Work

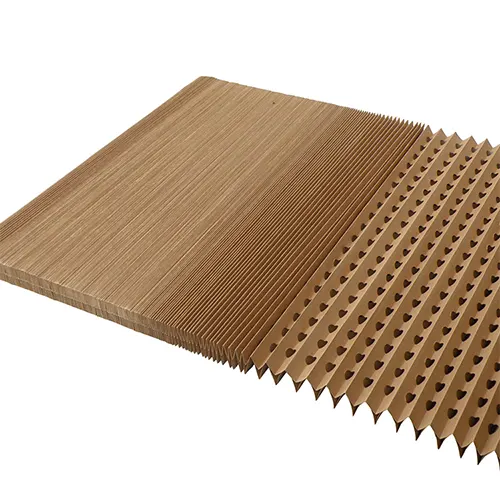

The filtration process of high temperature air filters involves trapping airborne particles within the filter media as air flows through it.

The materials used in these filters, such as fiberglass or synthetic fibers, are selected for their ability to withstand high temperatures while maintaining filtration efficiency.

The filter media is often densely packed to maximize the surface area available for trapping particles.

Applications of High Temperature Air Filters

1. Automotive Industry (Paint Spraying Booths)

In the automotive industry, high temperature air filters are crucial in paint spraying booths to ensure a flawless paint finish.

These filters maintain their efficiency under the high temperatures generated during painting and drying, effectively removing particulates that could compromise the paint job.

2. Food and Beverage Industry (Milk Powder Production)

High temperature air filters are essential in the food and beverage industry, particularly in the production of milk powder and infant formula.

They operate in modern milk dryers to filter out dust, bacteria, and other airborne particles, ensuring a sterile environment.

3. Pharmaceutical Industry (Depyrogenation Tunnels)

In the pharmaceutical industry, high temperature air filters are used in depyrogenation tunnels to maintain sterile conditions.

These tunnels expose glass vials and ampoules to high temperatures to ensure they are free from pyrogens and other contaminants.

The filters prevent particulates and microorganisms from entering, ensuring the effectiveness of the sterilization process.

CleanLink Offers Quality High Temperature Filters

The Importance of High Temperature Filters

Protecting Equipment and Processes

High temperature air filters are crucial for protecting sensitive equipment and processes from contaminants.

By removing particulates and dust, they prevent damage and wear, ensuring smooth operation and reducing maintenance costs.

Ensuring Product Quality and Safety

High temperature air filters can maintain high standards of product quality and safety by ensuring clean air. In industries like food, pharmaceuticals, and automotive, they prevent harmful contaminants from compromising product integrity and safety.

Compliance with Industry Standards

In the pharmaceutical industry, high temperature air filters are used in depyrogenation tunnels to maintain sterile conditions.

These tunnels expose glass vials and ampoules to high temperatures to ensure they are free from pyrogens and other contaminants.

Conclusion

High temperature air filters are essential in various industrial applications, providing critical protection for equipment and processes.

They ensure the safety, quality, and reliability of products by effectively removing contaminants from the air, even under extreme temperatures.

These filters help maintain sterile conditions and comply with stringent industry standards, safeguarding both equipment and end products.