Paint Booth 102: How to Measure Paint Booth Velocity

Photo by: Zell-8157

Photo by: Zell-8157

Paint booths are common and important to various industries, including automotive, aerospace, furniture, and many more. The velocity is a critical factor in ensuring the quality and safety of the painting processes.

The velocity of air within a paint booth directly impacts the efficiency of paint capture and the removal of contaminants.

What Is Paint Booth Velocity?

Paint booth velocity refers to the speed at which air moves through the booth during the painting process.

It’s a crucial parameter that influences the distribution of paint particles and contaminants in the booth.

Proper paint booth velocity is essential to achieve efficient overspray capture and maintain a safe environment for painters and the finished product.

Without the right velocity, paint particles can linger in the booth, leading to issues like uneven paint coverage and potential health hazards.

Paint Booth Velocity Measurement

How to measure

1. Taking measurements at various points within the booth helps identify any areas with irregular airflow.

We recommend that you measure velocity at the point where the painter usually stands.

2. Stand 3 ft away from the side walls as we find out that the measurement is down near 0 if we stand closer to the wall.

3. Paint booths that don’t have a proper seal at the door may experience a high airflow rate in the center of the paint booth. So avoid taking numbers at the center.

What is a good velocity rate in a paint booth?

According to OSHA Table G10 of 29 CFR 1910.94(c)6)(i) and NFPA-33, air flows of 75-125 feet per minute are recommended in cross-draft paint booths and 40-50 feet per minute in downdraft paint booths.

From expert experience, 100 fpm and 50 fpm are commonly used for cross-draft paint booths and downdraft paint booths respectively, which exceeds the 25% Lower Flammable Limit (LFL) requirement.

The airflow rate at this point shows high-quality paint finishes.

Air velocities below these recommended thresholds may still produce good paint finishes, but in general, lower booth velocities increase the likelihood of stratification, potentially leading to painting and heating issues.

This phenomenon is especially prevalent in larger rooms, such as aerospace, and heavy machinery paint booths. It’s important to note that downdraft booths tend to experience stratification at lower velocities compared to crossdraft booths.

Additionally, downdraft booths work efficiently removing overspray at lower velocities due to the downward motion of overspray particles, accelerated by gravity.

Addressing stratification can be a costly endeavor, as it always involves changing exhaust and supply fans,which could sometimes lead to structural modifications.

More Thoughts on Velocity

1. Regulation on velocity doesn’t guarantee a good paint job. Small air intake filter section may cause air turbulence and the overspray tend to settle on the surroundings, like walls, and ceiling. So adjust your air intake filters accordingly.

2. Find out how air flows in your booth and what your paint job requirements are. Even though cross-draft and downdraft are the main paint booth types on the market, there are many modifications. Take the actual need into account when calculating the velocity.

Conclusion

Understanding and effectively measuring paint booth velocity is crucial for achieving optimal painting results. Spray booth manufacturers recommend specific airflows tailored to the booth type, with crossdraft and downdraft booths requiring different velocity ranges.

Adjust your air intake filter sizes according to your paint booth velocity requirements. Clean-Link offers air intake and exhaust filter media for excellent airflow in paint booths.

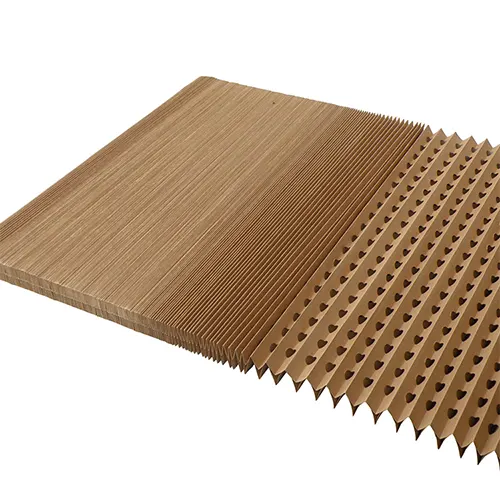

Air Filter Manufacturer: Clean-Link Paint Booth Air Filter Media

Made of synthetic fiber. Great paint mist capture ability. Good for air intake filter.

Pocket-shaped structure makes the filter surface twice larger than other paint booth media.

Not something you want? As an air filter manufacturer and air filtration solution provider, Clean-Link has a wide range of air filters available. Check out our product list for more air filters and filter media.

Talk to our expert team to get custom air filter media that perfectly fits your specific paint booth requirement. We also have a wide range of filters for your needs.