Air Filtration Applications For Animal husbandry

In terms of animal husbandry, people must be most concerned about the production capacity of livestock, the health of livestock itself, and the environmental problems of sheds. Many animal husbandry bosses are surprised: “why do others raise the same livestock as us? They also raise them in sheds, and the feed is the same. Why is our livestock incidence rate higher than others, and the production capacity is not as good as others?”

Next, Clean-Link will analyze the main reasons for this? And how to solve these problems.

First of all, we should know that when the feed, the environment outside the house and the variety of livestock are the same, the factor that can also affect the production capacity of livestock is the air environment inside the house. This factor is mainly composed of temperature, humidity, airflow, light, dust, microorganisms and harmful gases.

Air temperature in the room

Most of the sheds are closed well, which ensures the stability of the whole environment in the shed. Similarly, due to poor ventilation, the heat in the shed is not easy to be dissipated, and then the temperature in the shed is too high. The shelter with poor sealing has good ventilation effect, but the low temperature in winter will also lead to the low temperature in the house. Too high or too low temperature in the house will seriously affect the production performance of livestock.

Too high air humidity, too fast air velocity and too little light in the house will all lead to temperature reduction; On the contrary, it also makes the air temperature too high, which leads to the reduction of livestock production capacity.

Dust and microorganisms

Due to the excretion of livestock, microorganisms, dust and bacteria will breed. If the air circulation in the house is poor and microorganisms, dust and bacteria continue to accumulate, it will affect the health of livestock, such as foot-and-mouth disease, influenza, asthma, etc. This will directly reduce the production capacity of livestock and even lead to death.

Harmful gas

The breathing and excretion of livestock and the decomposition of organic matter will lead to the emergence of harmful gases, so the air composition inside and outside the house is very different. Excessive accumulation of harmful gases will also directly affect the health of livestock, resulting in reduced production capacity and even death.

Now that we understand these reasons, how can we solve the above problems? With our professional air purification technology and rich experience, Clean-Link has solved the above problems in the cooperation with Muyuan group.

Because the most important thing is to improve the air environment in the shed, it is necessary to install a ventilation system in the barn to stabilize the air temperature in the barn. Through the stable airflow, the accumulated dust, microorganisms, bacteria and toxic gases in the barn will be brought out of the shed, and the fresh air outside the shed will be introduced to balance the air quality in the barn.

Taking pig farms as an example, we put forward the following ventilation methods to improve the air environment and improve the production capacity of pig farms by integrating various elements such as season, the difference between male and female pigs, and the actual pig farm environment:

negative pressure ventilation and filtration

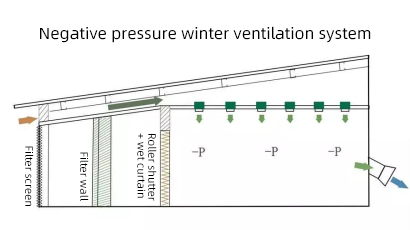

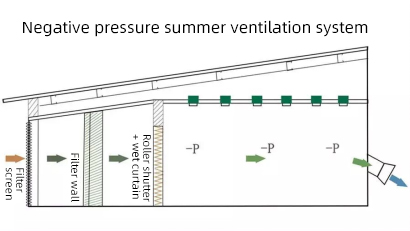

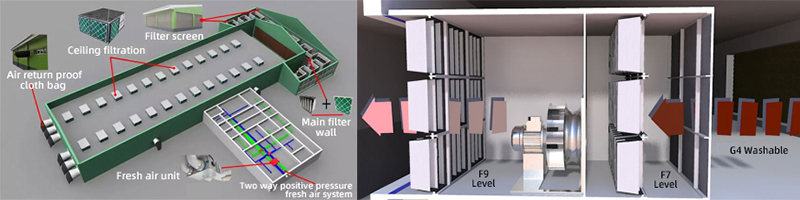

Negative pressure ventilation is to install the main filter wall in front of the cooling water curtain and the ceiling filter box on the ceiling ventilation window.

In winter, fresh air enters the ceiling through the top ventilation window and enters the pigsty after being filtered by the ceiling filtration system, and the waste gas is discharged by the fan.

In summer, fresh air enters the pigsty only after being filtered by the main filter wall, and the exhaust gas is discharged outside the pigsty by the fan. There is negative pressure inside the pigsty.

◆ negative pressure ventilation filter requires large area, low replacement frequency, low ventilation energy consumption and strong regional applicability.

◆ negative pressure ventilation should prevent the risk of unfiltered air entering the pig house through the gap, so the sealing requirements of the pig house are very high.

positive pressure ventilation and filtration

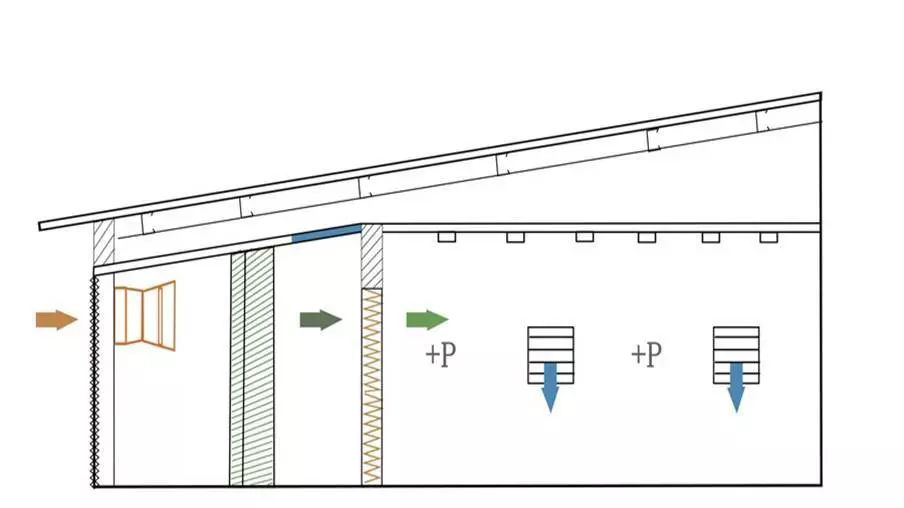

The main filter wall is installed in the filter room, and the positive pressure fan is installed in the front of the main filter wall. Fresh air enters the main filter wall through the filter screen and enters the main filter wall under the action of the fan.

In winter, the filtered air enters the ceiling through the ceiling ventilation window and enters the pigsty through the small ceiling window.

◆ the low risk of unfiltered air entering the house is the advantage of positive pressure ventilation, but the high fan power is the guarantee for the reliable operation of positive pressure ventilation. The selected fan must still be able to provide sufficient air volume under high static pressure difference.

Balanced ventilation or micro positive pressure ventilation

Neutral ventilation is between negative pressure ventilation and positive pressure ventilation, and generally adopts the mode of partial positive pressure, which is mainly used in boar stations. Neutral ventilation combines the advantages of positive pressure ventilation and negative pressure ventilation. The front end is positive pressure air inlet and the rear end is negative pressure exhaust, forming an orderly ventilation flow direction. However, relatively speaking, the investment is higher and the operation cost is better.

Then,how to choose a suitable filtration and ventilation scheme?

◆ the choice of filtration and ventilation scheme depends on the L6 or L9 epidemic prevention level of the air cleanliness of the pig farm and the region where the pig farm is located.

positive pressure ventilation and filtration is the preferred scheme for boar station and SPF original breeding farm;

Core population farm, a variety of schemes are used together to match different pig houses;

For areas sensitive to thermal emergency and pig breeds, it is recommended to adopt negative pressure ventilation and filtration design to ensure good ventilation effect and low energy consumption to meet the actual production needs.

During the use of the air filtration system, the following points need to be noted:

- The air tightness of the pigsty, the installation of the filter and the air flow mode in winter and summer should be tested before the pigsty air filtration system is put into use to ensure the operation effect of the system. When replacing the filter, special attention should also be paid to ensure safety. Pig houses with integrated positive pressure air filter units should use at least two units to ensure the positive pressure environment in the house when replacing the filter.

2. The system without unit shall have detailed operation instructions for filter replacement.

3. When to replace the filter is also a problem we need to consider. The best solution is to decide whether to replace it according to the pressure change of each layer of filter (the positive pressure air filter unit can be realized). However, many systems do not test the static pressure difference, and the filter can be replaced periodically.

Pig farm application scenarios: