What Are Pocket Air Filters? An Overview of Design and Function

Pocket air filters are a type of high-capacity HVAC filter designed with multiple pockets or bag-like sections that expand the surface area of the filter media.

This unique structure allows them to capture large volumes of dust and fine particles while maintaining steady airflow. By holding more contaminants than flat or pleated filters, pocket filters provide long service life and consistent efficiency.

They are widely used in commercial and industrial HVAC systems because of their ability to handle high airflow and demanding environments. Office buildings, shopping centers, hospitals, manufacturing facilities, and airports often rely on pocket air filters to protect both occupants and equipment.

Their durability, energy efficiency, and superior dust-holding capacity make them an essential solution for maintaining indoor air quality in large-scale ventilation systems.

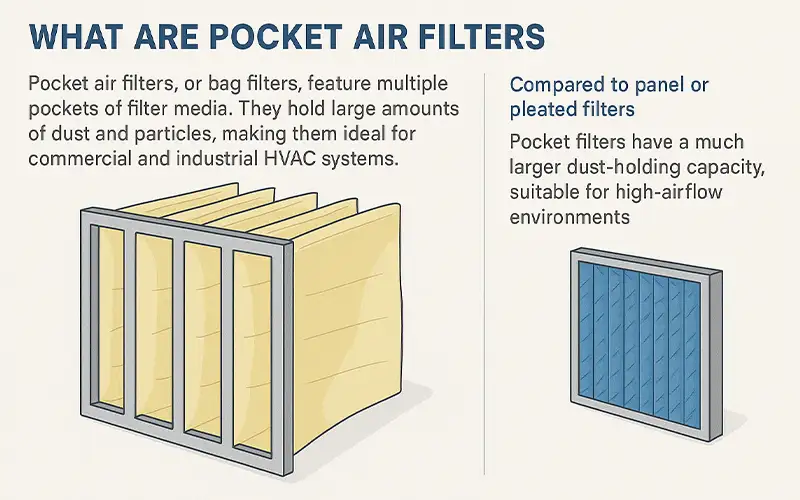

What Are Pocket Air Filters?

General description and purpose

Pocket air filters, also known as bag filters, are high-capacity HVAC filters designed with multiple deep pockets of filter media.

These pockets expand the effective surface area, enabling the filter to capture large amounts of airborne dust and fine particles without quickly clogging.

Because of their dust-holding capacity and efficiency, pocket air filters are ideal for high-airflow systems in commercial and industrial environments.

According to the U.S. Environmental Protection Agency (EPA), selecting the right filter type is crucial for maintaining indoor air quality and protecting HVAC systems.

How they differ from panel or pleated filters

Unlike panel or pleated filters, which are generally thinner and best suited for residential or light commercial use, pocket air filters are designed to perform in larger systems with higher airflow demands.

Their bag-like design holds significantly more dust and debris than flat or pleated filters, which means longer service intervals and reduced maintenance frequency.

While pleated filters are effective in smaller systems, pocket air filters are often chosen for environments such as hospitals, shopping centers, and factories where continuous operation and consistent efficiency are essential.

The ASHRAE guidelines note that multi-pocket filters can provide superior efficiency while managing airflow resistance effectively.

Pocket Filter Design and Structure

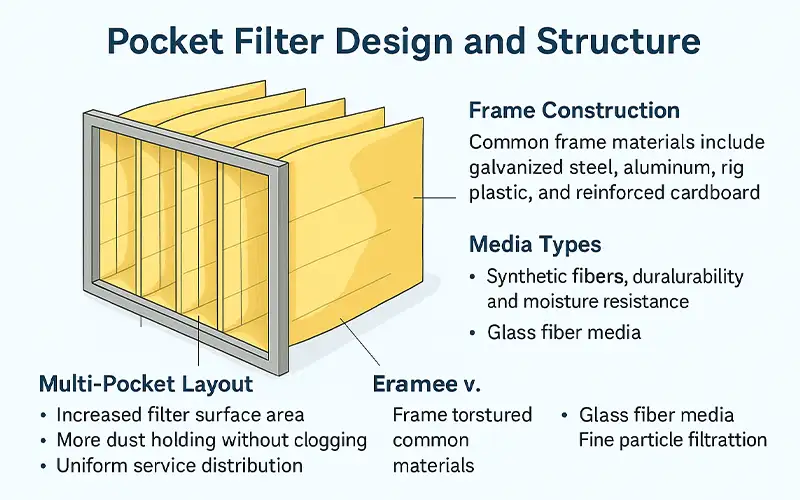

Multi-pocket layout to increase filter surface area

Pocket air filters are designed with multiple pockets or bag-like extensions that significantly expand the total surface area of the filter media.

This increased surface allows the filter to hold more dust and debris without clogging, resulting in longer service life and stable performance.

The design also ensures uniform airflow distribution, which minimizes resistance and improves overall HVAC efficiency.

According to ASHRAE, larger media surface areas improve particle capture while maintaining manageable pressure drops.

Frame construction: metal, plastic, or cardboard

The frame of a pocket air filter is built to support the weight of the media and maintain shape under varying airflow conditions. Common frame materials include galvanized steel, aluminum, rigid plastic, and reinforced cardboard.

Metal frames are durable and suitable for demanding industrial environments, while plastic and cardboard options are lighter and often used in standard commercial HVAC applications. Frame choice depends on airflow pressure, humidity levels, and replacement cycles.

Media types: synthetic fiber vs. glass fiber

Pocket filters are manufactured with either synthetic fibers or glass microfiber media. Synthetic media is durable, resistant to moisture, and less prone to microbial growth, making it ideal for humid or variable environments.

Glass fiber media offers excellent fine particle filtration and heat resistance, often used in facilities requiring higher filtration precision.

The EPA highlights that filter media type affects both efficiency and energy consumption, making proper selection critical for balancing performance with operating costs.

How Pocket Air Filters Work

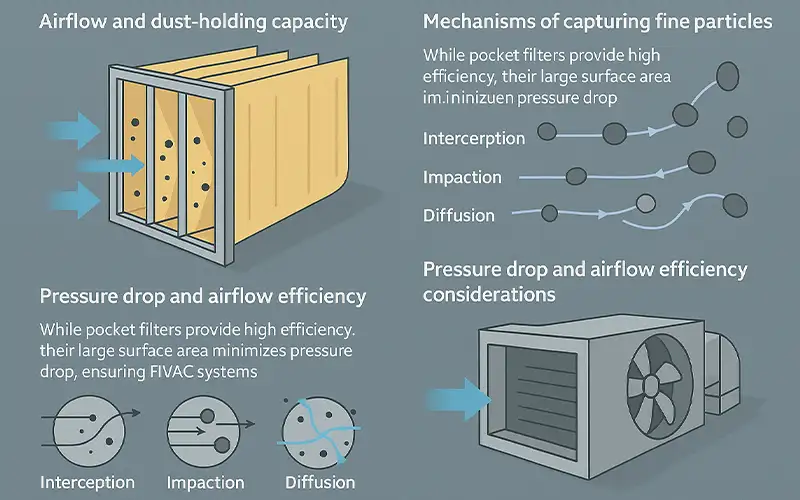

Airflow and dust-holding capacity

Pocket air filters are engineered for high-volume airflow while maintaining effective particle capture.

Their multi-pocket design increases surface area, allowing them to hold more dust and contaminants compared to flat or pleated filters. This higher dust-holding capacity extends service life and reduces the frequency of filter changes, which is why they are widely used in commercial and industrial HVAC systems.

According to ASHRAE, filters with greater surface area perform better under demanding airflow conditions without excessive resistance.

Mechanisms of capturing fine particles

Pocket air filters capture contaminants using several physical mechanisms:

Interception

Particles following airflow paths come into contact with fibers and stick.

Impaction

Larger particles deviate from airflow streams and collide with fibers.

Diffusion

Ultrafine particles move randomly and are more likely to attach to fibers.

These combined mechanisms allow pocket filters to trap a wide range of pollutants, from coarse dust to finer particles such as pollen and mold spores.

The U.S. Environmental Protection Agency (EPA) emphasizes that filters using multiple capture methods are more effective in improving indoor air quality.

Pressure drop and airflow efficiency considerations

While pocket filters provide high efficiency, their large surface area helps minimize pressure drop, ensuring that HVAC systems can circulate air without unnecessary strain.

Maintaining this balance is essential, as a filter with excessive resistance can reduce airflow, increase energy consumption, and stress system components.

Pocket filters are designed to optimize particle capture while keeping energy efficiency in mind, making them cost-effective solutions for facilities that require continuous operation.

Advantages of Pocket Air Filters

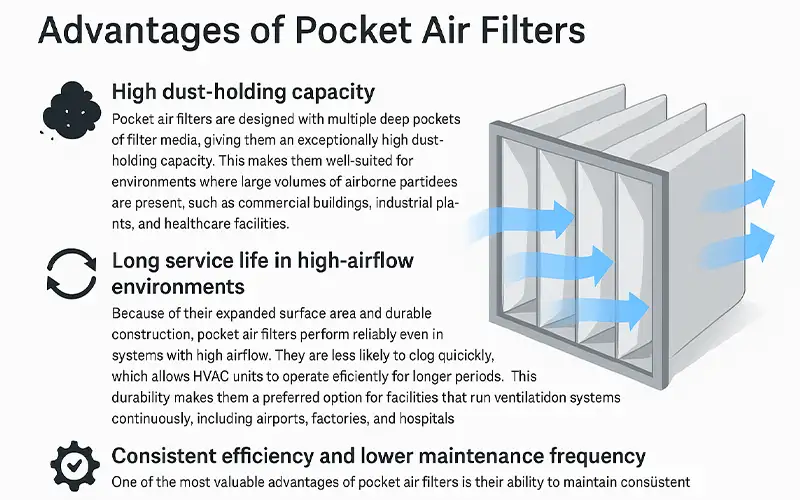

High dust-holding capacity

Pocket air filters are designed with multiple deep pockets of filter media, giving them an exceptionally high dust-holding capacity.

This makes them well-suited for environments where large volumes of airborne particles are present, such as commercial buildings, industrial plants, and healthcare facilities.

Their ability to capture and retain more dust extends their operational lifespan and reduces the frequency of replacements compared to standard filters.

Long service life in high-airflow environments

Because of their expanded surface area and durable construction, pocket air filters perform reliably even in systems with high airflow.

They are less likely to clog quickly, which allows HVAC units to operate efficiently for longer periods. This durability makes them a preferred option for facilities that run ventilation systems continuously, including airports, factories, and hospitals.

Consistent efficiency and lower maintenance frequency

One of the most valuable advantages of pocket air filters is their ability to maintain consistent efficiency throughout their service life.

While some filters lose effectiveness as they accumulate dust, pocket filters continue to capture particles effectively until they reach their dust-holding limit.

This consistent performance reduces the need for frequent maintenance, lowers labor costs, and ensures steady indoor air quality over time.

Common Applications of Pocket Air Filters

Commercial buildings and offices

Pocket air filters are widely used in office buildings, retail centers, and other commercial spaces to maintain a clean and healthy indoor environment.

They reduce dust and allergens in the air, helping to create a more comfortable space for employees and customers while protecting HVAC systems from contamination.

Healthcare facilities and laboratories

Hospitals, clinics, and laboratories require high levels of air cleanliness to protect patients and staff.

Pocket air filters are often used as part of multi-stage filtration systems in these environments. Their high efficiency and dust-holding capacity make them reliable prefilters to extend the life and performance of HEPA filters used in critical areas.

Manufacturing and industrial facilities

In factories and industrial plants, airborne particles from production processes can place heavy demands on HVAC systems.

Pocket air filters are a strong choice for these settings because they can handle high airflow and capture large volumes of dust, fumes, and fine particles, ensuring compliance with air quality standards and protecting machinery.

Airports, schools, and large public buildings

Large public spaces with high foot traffic, such as airports, schools, and universities, rely on pocket air filters to maintain consistent indoor air quality.

Their long service life and ability to perform well in continuous operation make them ideal for environments where ventilation systems must run around the clock.

Maintenance and Best Practices

Replacement guidelines

Pocket air filters should be replaced based on either time intervals or pressure drop readings, whichever comes first.

In most commercial HVAC systems, replacement is recommended every 6 to 12 months. However, in environments with heavy dust loads or continuous operation, filters may need to be changed more frequently to maintain efficiency and airflow.

Monitoring with pressure drop gauges

The most reliable way to determine when a pocket filter needs replacing is by monitoring pressure drop across the filter.

As dust accumulates, resistance increases, forcing the HVAC system to work harder. Installing a differential pressure gauge allows facility managers to track performance and schedule timely replacements before efficiency is compromised.

Cost-effectiveness of proper maintenance

Regular maintenance of pocket air filters reduces energy consumption, prevents system strain, and ensures consistent indoor air quality.

Although pocket filters have a higher upfront cost compared to pleated or panel filters, their longer service life and reduced replacement frequency make them cost-effective in the long term.

Well-maintained pocket filters also extend the lifespan of downstream filters, coils, and other HVAC components, further lowering overall maintenance expenses.

Final Thoughts

Pocket air filters play a critical role in maintaining indoor air quality for commercial, industrial, and public facilities. Their multi-pocket design delivers high dust-holding capacity, long service life, and consistent efficiency, making them ideal for high-airflow environments where reliability is essential.

Compared to pleated or panel filters, they offer superior performance and serve as an effective prefiltration step for HEPA systems in sensitive applications.

For facility managers and building operators, choosing pocket air filters means investing in cleaner air, energy efficiency, and long-term cost savings.

Evaluating current HVAC filtration strategies and upgrading to pocket filters where appropriate can lead to healthier environments, reduced maintenance, and improved system performance.

Now is the time to assess whether your HVAC system could benefit from the reliability and efficiency of pocket air filters.

Explore available options, match the right media type to your environment, and take a step toward ensuring cleaner air and stronger system protection.